Tamtron’s Lahti unit has a long history of implementing mixing solutions for various industries. Due to the increasing demand for battery metal applications, Tamtron has invested in the development of mixing solutions to better meet the needs of this growing industry. In this article, Janne Kousa, Tamtron’s technonology directror for key technology development and design, explains more.

Flexible battery metal mixing solutions

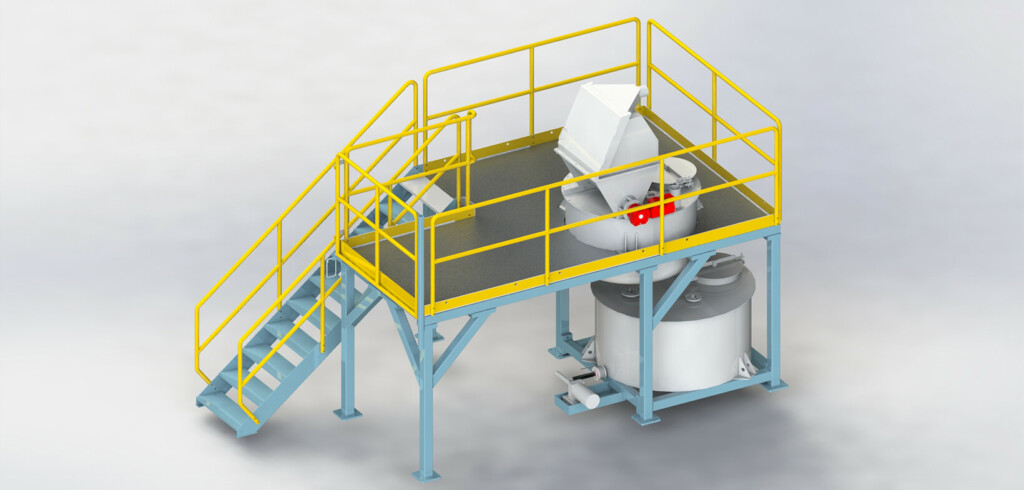

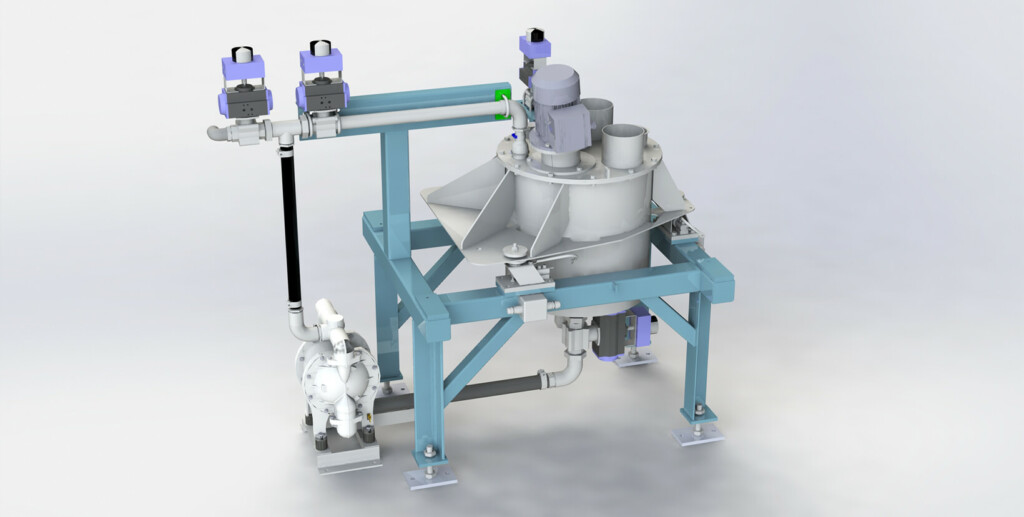

In the battery industry, there is often a need to feed materials (such as lithium, cobalt, or nickel) into the process, either as the main component or through an additional dosage. Tamtron is able to offer flexible solutions, for example, to integrate the handling of big bags directly into the tank, allowing the media to be mixed and fed into the process pipe.

The system is modular and flexible, allowing for changes in capacity, materials, and big bag sizes. The concept can be modified retrospectively according to any changes in the manufacturing process. The mixers can be used for the treatment of battery metals, black mass, and precursors, and Tamtron also has experience in sludge treatment.

Solid experience and versatile service

Tamtron mixing equipment is designed to meet the industry’s stringent material requirements. The equipment is available as stand-alone units, fully electrified and incorporating their own PLC controllers. The supplied units can also be controlled directly via DCS or, where applicable, as a hybrid according to the customer’s own requirements. If required, Tamtron can also design Atex-compliant equipment.

Tamtron offers solid mixing solutions experience and flexible service, whether the customer is in the design phase of a material handling project, piloting a new process, or making additional purchases for a plant that needs to introduce a second material supply line or make other changes to an existing main process.

Download a guide to purchasing weighing and dispensing solutions for the battery industry

Our guide will help especially designers and those responsible for project and purchasing management to choose weighing and dispensing solutions for the battery industry. It provides information on the issues to consider, whether for battery production or recycling

Interested in weighing insight?

Subscribe to our newsletter, and you’ll receive an email a few times a year with up-to-date information on weighing and dosing solutions.