An essential part of Tamtron’s extensive range of weighing solutions is the On-board. The difference with the weighing solutions for heavy vehicles, i.e., train and truck scales, is that the on-board weighing solutions are mounted on mobile equipment and weighing takes place while the material is being handled.

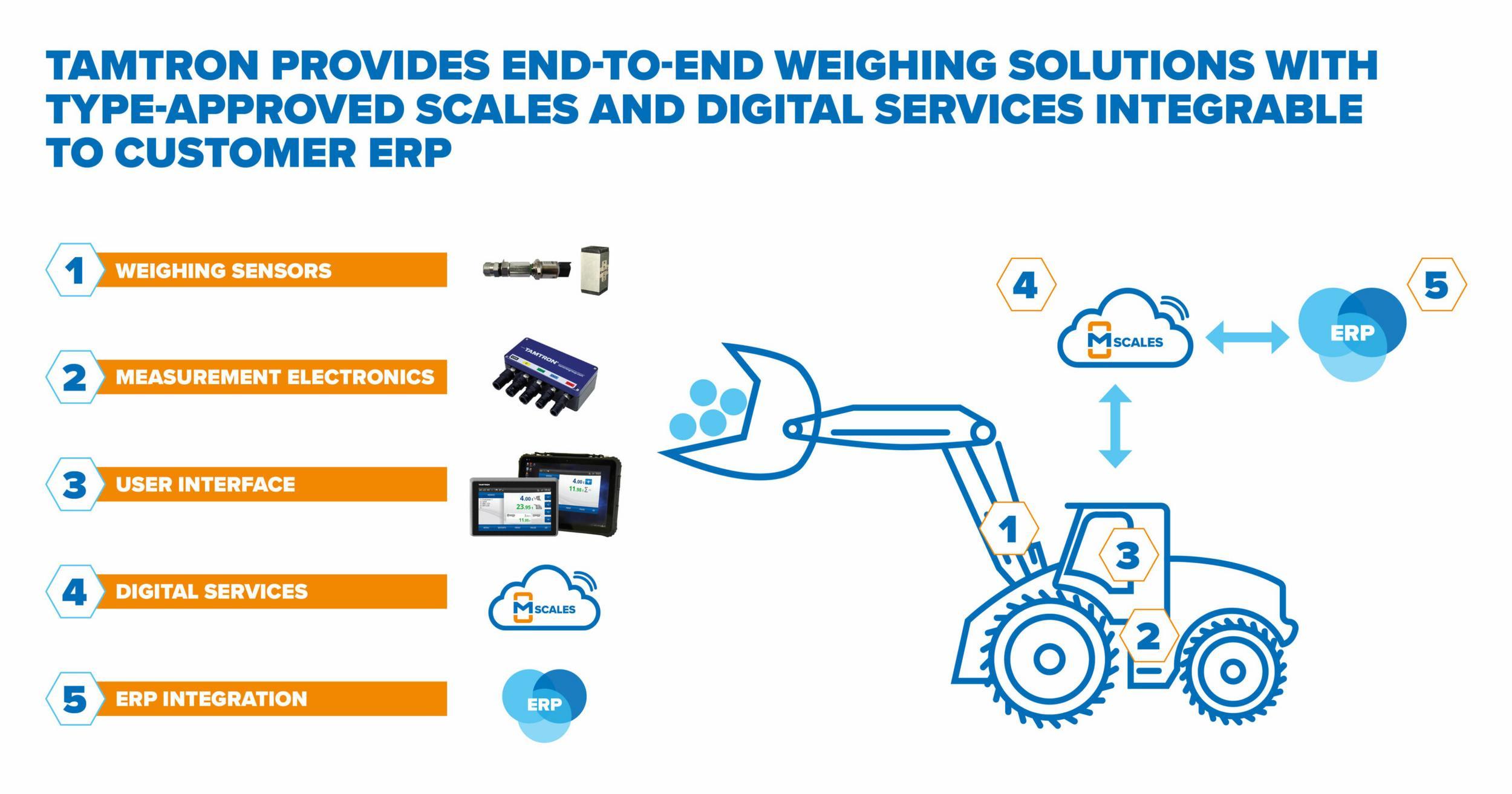

With On-board solutions, material weighing can be executed effortlessly during transfer and loading without slowing down the production process. This alone streamlines operations in many ways, but like other Tamtron weighing solutions, On-board scales can be connected to the cloud and to the customer’s ERP system, further streamlining production and logistics processes and improving business productivity.

In his article, product Manager Harri Pentinniemi explains more about Tamtron’s weighing solutions for mobile equipment.

On-board solutions for a wide range of industries and different types of machinery

Tamtron’s On-board weighing solutions originate from the wheel loader solution we started to develop back in the 1980s. In the beginning, it was a static method where the boom of the machine was halted in place to collect weighing data. Since then, our solutions have evolved to the extent that today weighing data can be collected while the machine is moving and during lifting. What is best, the weighing does not slow down the customer’s processes.

Our mobile equipment weighing solutions are available for a wide range of industry segments and different types of machinery. For the forest industry, One Bioforest and One Timber Crane Scales provide real-time weighing of the amount of timber being moved and loaded from the logging site. The Tamtron One Power Container Stacker and Straddle Carrier Scales accurately weigh the gross mass of shipping containers in compliance with the SOLAS regulations.

In addition to wheel loaders, on-board scales can be installed on forklifts, reach stackers and material handling equipment in the materials sorting sector, dumpers in the earthmoving and mining industries, and waste trucks and material handling equipment in the recycling sector.

Such a diverse range of industries requires a broad range of skills from us at Tamtron, combining mechanical and IT and engineering skills with expertise in production, process, and logistics. On the other hand, this extensive know-how enables us to help our customers to collect and manage reliable weighing data in a timely manner while on the job.

Naturally, our On-board scales are type-approved for commercial use with verified weights, which allows using the weighing data directly as the basis of invoicing.

On-board weighing solutions are delivered to customer requirements

The supply of scales for mobile machinery starts with identifying the customer’s needs. The first step is to determine whether the customer only wants to know the weight of the material or whether the weighing process should be accompanied by data transmission and integration capabilities. This is how we find the suitable scale model for the customer’s needs. The next step is to agree with the installation team leader on a time and place for the installation.

The weighing data stored in the Tamtron scale’s memory can be printed out on a weighing-by-weighing basis or transferred for business use via USB, cloud service or integration directly into an ERP or other system.

If the customer needs a cloud service, the scale installation is followed by the deployment of Tamtron’s Cloud service. This involves creating an account for the customer and discussing together what data the customer wants to process and transfer. This could be, for example, the end customer’s name and location, the vehicle’s registration number and, of course, the weighed material and its quantity.

Suppose the customer also wants the weighing system to be integrated into their own ERP system. In that case, we provide interfaces and instructions, after which the customer handles the integration work with an external IT provider with our assistance.

Seamless transfer of weighing data to cloud and ERP meets the demands of digitalization

Cloud services have been part of Tamtron’s On-board solutions since the early 2000s, but especially recently, they have developed enormously. Today, customers increasingly demand data about their operations – often in real-time. This is understandable in a weighing business, where optimal loads and information on quantities, materials and schedules transferred improve business efficiency and bring transparency to processes, enabling the best possible performance. This information helps to optimize operations for maximum fluidity and efficiency as well as facilitates reporting between partners.

With Tamtron’s weighing solutions, the driver of, for example, a wheel loader receives an order directly to his machine, where he selects it on the screen. The necessary information can be set on the order already at the office, which also reduces the driver’s potential errors and makes the job easier and faster – once the order is opened, all the driver has to do is to load.

Once the weighing is complete, the benefits of the digital system become even more tangible. Transferring the weighing result from the scale to the cloud or to the customer’s ERP system and thus to the invoicing system prevents errors and speeds up and streamlines the work. For example, it avoids the need for someone to manually enter data or search for a particular receipt among hundreds of others or the risk of a record being lost or misplaced, which would typically lead to invoicing losses. The system can easily provide a range of rich and valuable reports that can be used to further streamline and improve operations.

Cloud service is a cost-effective solution in many respects. Still, its ease of use and the numerous business benefits it brings – most notably the fact that it allows all weighing tons to be invoiced – it is not really a cost at all.

Tamtron's On-board solutions weigh the future

The feedback we receive from our On-board weighing solutions is positive across the board. When customers get to test the new weighing solution or integration , the comments are primarily about how much easier and simpler the work has become and how the weighing process has become error-free at the same time.

Even though we at Tamtron have been manufacturing and developing weighing solutions for decades, we must constantly keep up with the times and look at what new features are needed in our existing solutions or what completely new solutions we should develop. We are constantly in touch with our customers and listen to their needs. It is important to us that our weighing solutions make our customers’ work as easy as possible and add value to their business.

Not only are we constantly developing our scales to be more accurate and our solutions to meet the demands of digitalization and automation, we are also leading the way in these areas ourselves. Tamtron’s next-generation SaaS technology and cloud services are in a class of their own and are already at the core of our operations. Alongside the integration of our hardware and software, we are leading the way in integrating the weighing industry into increasingly automated production chains.

Of course, developing scales and services is about more than just keeping abreast of market and technological developments in general. Our solutions reflect decades of experience and long and close cooperation with our partners and key customers, which will not diminish in value in the future. As we manufacture our scales and provide our services specifically for our customers, we listen carefully to their needs and wishes, now and in the future.

Interested in weighing insight?

Subscribe to our newsletter, and you’ll receive an email a few times a year with up-to-date information on weighing and dosing solutions.