Tamtron’s Lahti unit has a long history and extensive experience in supplying equipment to the paper and wood processing industry. The industry has played a significant role in the career of Pekka Huusko, who works in sales of the aforementioned products and services at Tamtron. However, Huusko considers he has left his mark on the paper industry as well. Although he has been familiar with the industry for decades and has developed routines, working in the customer interface teaches even the experienced expert new things. This in turn continues to fuel Huusko’s enthusiasm and motivation. In his article, he talks about the solutions Tamtron offers for the paper and wood processing industry.

Equipment supply for the paper and wood processing industry

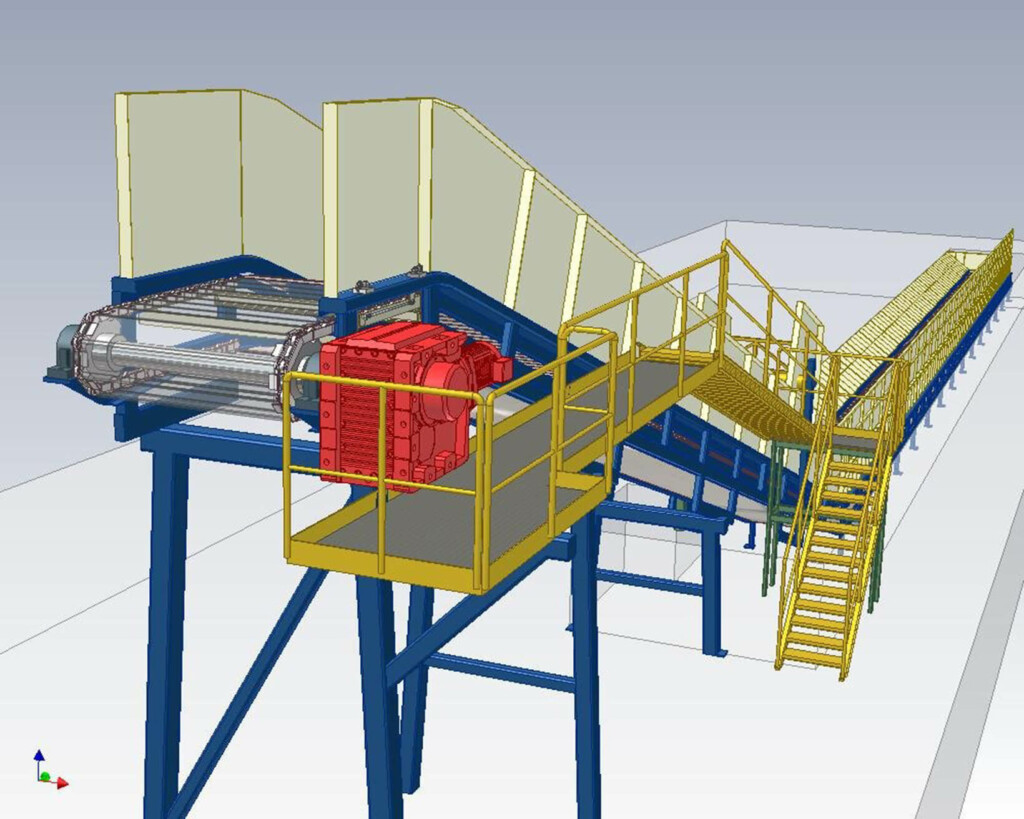

Various types of equipment used in the paper and plywood industry were added to the range of Tamtron’s Lahti unit in connection with the acquisition at the turn of the millennium. Since then, the unit has designed, manufactured, and installed pulp pallet conveyors, reject conveyors (to recycle broken paper or board for the production of primed paper and board), and their accessories for the paper and board industry. Project deliveries therefore often include, for example, removal equipment for pulp bales binding yarn.

Conveyors are purchased to be used for decades, so they are a very long-term investment. This requires sufficiently strong structures and high-quality materials and components. In Finland there are still conveyors in use that werer manufactured as late as the 1990s. Tamtron’s customer companies are mostly so large that the machines are maintained and serviced by their own maintenance organisation, which replaces chains, bearings and other wearing parts for the equipment. Naturally Tamtron supports its customers with all the necessary expertise, service and spare parts.

In addition to conveyors, Tamtron offers glue kitchens for mixing glue, which is widely used in the plywood industry. Glue kitchens often also include automation that can be connected to factory automation systems. Tamtron often delivers the equipment installed and carries out commissioning and testing, especially for automation.

Equipment tailored to needs and facilities of paper and wood processing industry

Tamtron often receives different ideas and thoughts from its customers on how to build the equipment or facility. The company’s task is to work with the customer to find optimal solutions that are feasible in practice and allow the customer to achieve the benefits of the agreed technical solutions.

As no new paper mill has been built in Finland for more than 20 years, the conveyors and other equipment to be modernised have to fit into the existing, sometimes cramped spaces and layouts. The design process therefore always involves a considerable amount of work and often the task is to tailor the equipment to the customer’s premises. This requires Tamtron to draw on the lessons learned from long experience and to be flexible during the design phase.

Paper and wood processing industry customers help develop equipment and services

Control and electrical automation technologies are constantly evolving and are naturally areas of interest to customers, offering greater efficiency and competitiveness by reducing manual work. Tamtron has been refining its solutions for more than 30 years, striving to deliver more and more added value to its customers. When you listen carefully to the customer and their user experience, there is always a little more to offer. It could be said that genuine listening and attention to the customer is something that allows even the most experienced operator to continue to improve.

The paper industry is not a dwindling sector, despite the occasional negative headlines in the news. Trends vary from sector to sector, so even in paper and wood processing, a line closure in one industry can mean a plant opening or other investments elsewhere. Investments in the paper industry are made for the long term.

Tamtron’s strength compared to many other players in the industry is its long experience. The company’s history is rich in deliveries to factories where its equipment is still in use. The combination of positive experience and a long history has created an unrivalled credibility that allows Tamtron’s experts to bid and deliver projects today that will serve companies for decades to come.

Tamtron acquired Lahti Precision’s business in 2023 and will continue to operate under the Tamtron brand.

Guide to designing scales and weighing systems

Our guide provides designers and those responsible for purchasing a weighing system with information and advice on the needs of modern design and how to get the most out of a weighing system to benefit your business.

Interested in weighing insight?

Subscribe to our newsletter, and you’ll receive an email a few times a year with up-to-date information on weighing and dosing solutions.