Among railway weighing systems that have been approved for commercial use, The Tamtron Trapper train scale system is the best on the market. Large steel mills, national transport operators and oil refineries across the globe rely on Trapper’s excellent accuracy.

Through technology and know-how Tamtron has become the world leader in the specialized field of railway weighing. This development has a long history but is also a timely topic as the need for railway weighing solutions has grown more and more during recent times. But where does this technology stem from, where is it going and what are its benefits?

In his article the CTO of Tamtron Czech Republic, Jaroslav Hronek shares his knowledge on the past, present and future state of Tamtron’s railway weighing systems.

Railway weighing systems increasingly relevant

In the transport of goods, a general trend of returning from road to railway can be observed. This is due to many factors such as environmental awareness, saturation of the road network and rising fuel prices. At present, unified transport systems such as the Innofreight container system are gaining importance. This is a significant contribution to the logistics of goods as it speeds up transport and reduces its costs.

A secondary benefit of the system is the simple and thus inexpensive construction of railway wagons for container transport. Nowadays, not only conventional containers but also containers for the transport of bulk materials and liquids are available.

Dynamic weighing systems that allow the weighing of wagons on the move at higher speeds and minimize the requirements for intervention in the construction of the railway track are very well demanded.

The history of railway weighing solutions and Tamtron are interlocked

The need for railway weighing solutions is practically as old as railways themselves. During the early times the weighing was achieved with a static mechanical bridge scale on which individual wagons were weighed. With the development of electronics, these mechanical systems began to get replaced with electromechanical sensors (strain gauges) and measuring electronics. These systems are still used today for some weighing applications, such as filling rail cars with material (mostly bulk or liquids) to the required value.

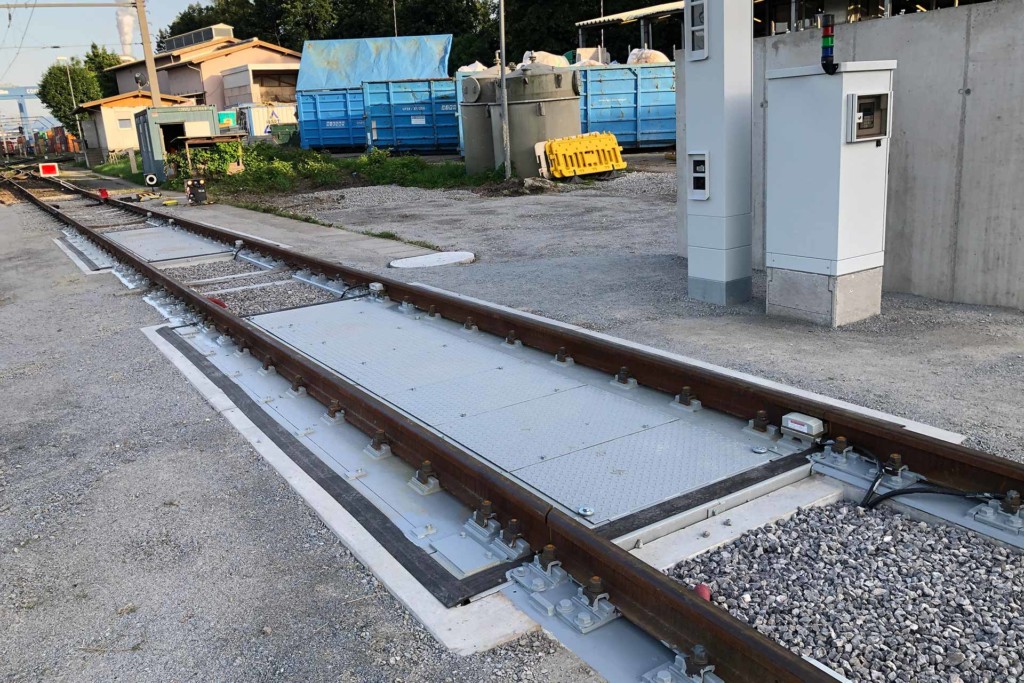

The static method, where the wagon had to be placed on a scale and remain stationary for a certain period of time during weighing, was very time consuming and did not meet the needs of the increasing transport of goods and its efficiency. This called for the development of dynamic weighing systems, where individual wagons could be weighed on the move. This means that individual wagons of a train set can be weighed automatically as they pass the weighbridge, and their weights evaluated by a weighing computer system.

Tamtron’s own history in the field of railway weighing solutions is linked to the issue of dynamic weighing. As one of the pioneers in this field, Tamtron has created new and original solutions for decades. The first Tamtron Trapper DRS dynamic weighing systems were installed already back in the 1980s. Over time, Tamtron has developed into a world leader in this specialized field and nowadays offers several types of dynamic railway weighing systems.

Tamtron stands out with the range of knowledge in railway weighing

The longevity of Tamtron and its operations in railway weighing systems has enabled the company to accumulate a tremendous amount of invaluable knowledge and know-how. It has gradually developed over time and is based on hundreds of dynamic weighing system implementations all over the world. On the other hand, know-how is exactly what is needed for longevity and is in fact one of the cornerstones of our success.

Railway weighing solutions are a very specific field from the perspective of the Tamtron product portfolio.

They are not about the sales of “finished goods”, but the implementation of relatively large-scale projects of which the railway weighing system is a key component. Each of these projects is always unique in some way.

The uniqueness in turn is especially due to the range of knowledge required in various branches. Additionally, the length of implementation from the customer’s idea to the installation of the equipment, the need for cooperation with other parties who are often Tamtron’s subcontractors, the high project complexity and, last but not least, the financial volume of individual projects plays great parts.

What is also noteworthy, is that for the success of this business expertise is essential not only in the field of weighing technology itself, but in other fields also. These are mainly railway infrastructure construction, railway line operation, railway line design, knowledge of rolling stock construction and operation, as well as design for railways in general. Naturally knowledge of the design and manufacture of steel and concrete structures and of logistics in railway cargo transport is also important.

World leader in railway weighing but other weighing as well

Solutions for railway weighing systems make up a significant part of Tamtron’s turnover. However, in addition to long-standing presence on the market and high level of know-how, Tamtron’s leading market position is the result of continuous development and modernisation of all its weighing systems. The services provided to our customers are also an important factor in our success. In particular aftersales services that are provided after commissioning and during the usage of the equipment.

The quality of our products and their high reliability, durability and long lifetime are a matter of course for us. All this is only possible thanks to the fact that Tamtron has a stable team of top specialists in all fields of our operations. This means from software and HW developers, service technicians, designers, production, output control and marketing staff to the provision of administrative activities.

We must also not forget the excellent work of the management, which creates and ensures stable conditions for all operations. The combination of all these factors is a reflection of Tamtron’s market position and success and gives great promise for future growth.

Railways to the future

The main factor behind the quality and high technical level of Tamtron’s railway weighing system is our long history in the branch. All the experience gained from hundreds of projects materializes in our solutions.

Our ability to recognize the needs of the market and thus always be one step ahead in the development of new solutions is crucial also for further success. In the development our sights are mainly on solutions for high-speed fully automatic logistics systems consisting of weighing systems and integrated automatic OCR identification systems – a combination that digitises railway logistics.

We also see the future primarily in providing complete data to the users of the system. This means creating cloud solutions where the weighing systems will be the source of raw data for the cloud services.

Thanks to the combination of all relevant knowledge and know-how, Tamtron is able to further develop and offer original solutions that will maintain its position as the world leader in its profession. Tamtron’s train is truly on track.

Interested in weighing insight?

Subscribe to our newsletter, and you’ll receive an email a few times a year with up-to-date information on weighing and dosing solutions.